Artificial Textures

It is now possible to see a 3D printer on almost every desk. Professionals or amateurs, industry or entertainment, all audiences use 3D printers. 3D printers, which have lost their fascinating air, are now a part of our lives.

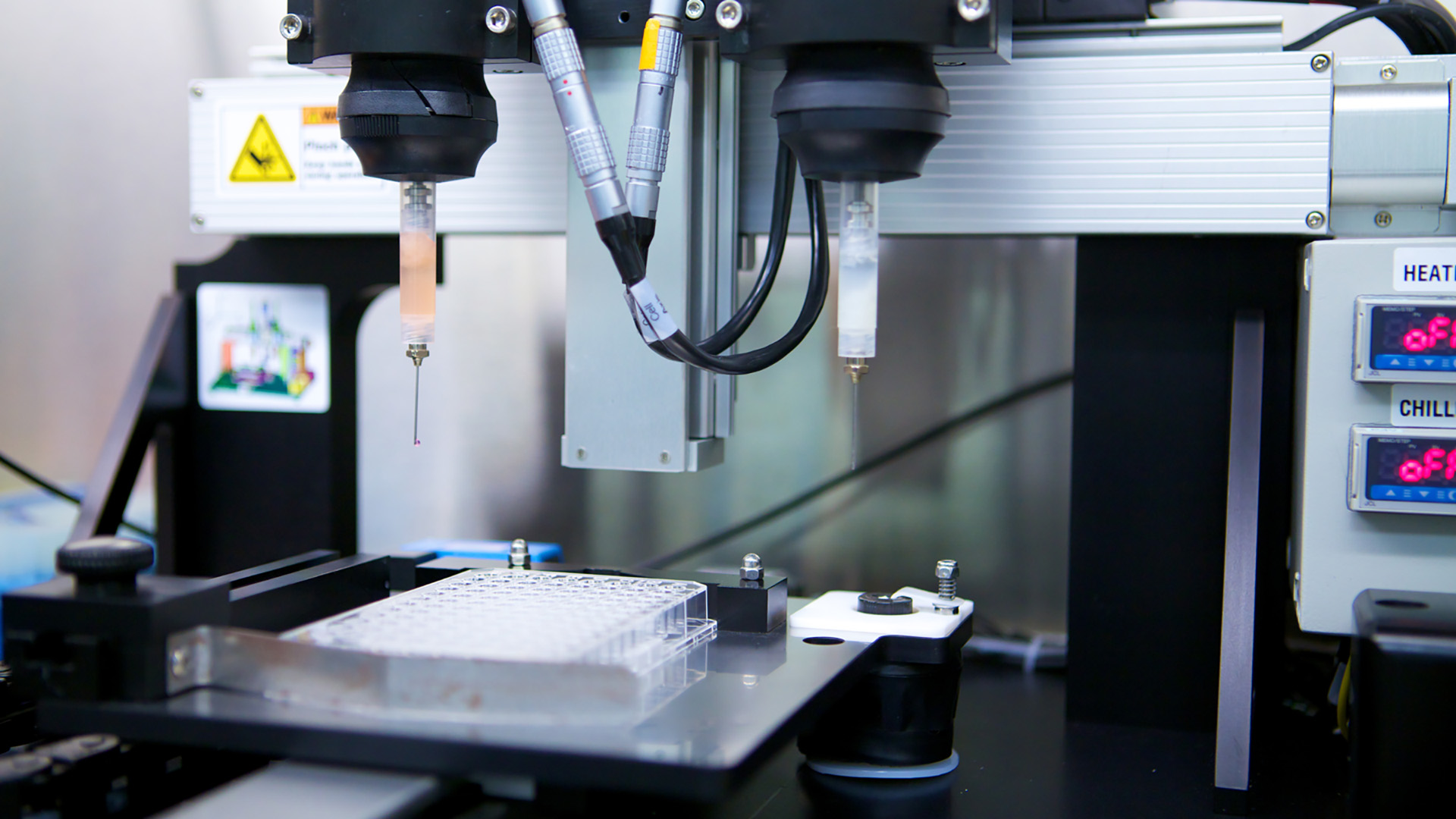

It would not be wrong to say that the health sector is the sector that makes the most use of 3D printers. In addition to saving many lives during the pandemic, it is also the only solution for research and product production in many areas in the health sector.

.jpg)

Inspiration for medical innovation can come from anywhere. As an example, University at Buffalo researchers have developed a new method for creating 3D artifacts, inspired by children's books. In a series of experiments, the researchers used the compressive buckling method to fabricate a variety of three-dimensional polymeric structures. These include simple shapes such as a box and a pyramid, as well as more complex displays such as a sound wave and an eight-legged design resembling an octopus. To demonstrate the method's utility in tissue engineering, the team created an osteon-like structure. The osteon is the basic structural unit of bone tissue and is characterized by sparsely distributed osteocytes in the mineral bone scaffold. Each osteocyte resides in a small space known as the lacuna, and the different osteocytes are connected via canaliculi, which are small channels in the bone scaffold.

.jpg)

Artificial tissue method developed by University of Buffalo researchers Ruogang Zhao, PhD, associate professor of biomedical engineering at the University of Buffalo, said the results are important because most tissue engineers use two-dimensional images to create very thin artificial tissue that does not represent the volume of human tissue. relies on tissue production methods. The planar nature of these artificial tissue models limits their applications in disease modeling and drug testing, he said. "When you turn a new page, you create power. This force pulls on the feet of the figure, causing the folds to open and the figure to come out," said Zhao, one of the study's authors. "With this study, we showed that the same principle can be applied to artificially engineered tissue." The compressive buckling method can be used to rapidly transform a two-dimensional artifact into a three-dimensional artifact of significant thickness, allowing researchers to create more realistic tissue and opening up new possibilities in tissue engineering and regenerative medicine. Zhao also said it has the potential to outperform other 3D tissue engineering methods such as 3D bioprinting in terms of fabrication speed and spatial resolution.

3D printers, which have a simple but effective structure, do not surprise us anymore, and we will say that 3D printers can make even our homes if we can, because there is no limit with 3D printers.