Engineering Plastics: Strong And Diverse Materials İn Industrial Applications

Engineering plastics are special plastic materials widely used in industrial applications. These materials are known for their high-performance properties and are often preferred in complex engineering projects. The properties of engineering plastics can meet various industrial requirements such as durability, strength, chemical resistance and high temperature tolerance. In this article, we will take a detailed look at what engineering plastics are, their properties, applications and advantages .

Definition of Engineering Plastics

Engineering plastics are special plastic materials that are generally produced from thermoplastic or thermosetting plastics and have high-performance properties. These materials are specifically designed with their chemical formulations and manufacturing processes and are optimized for use in a variety of industrial applications.

Properties of Engineering Plastics

Durability: Engineering plastics generally have high durability, making them resistant to mechanical stresses, impacts and abrasion.

Strength: These plastics generally have high strength, allowing them to be used in structural applications.

Chemical Resistance: Engineering plastics are generally resistant to chemicals, making them safe to use in industrial environments.

High Temperature Tolerance: Some engineering plastics are resistant to high temperatures, allowing them to be used in high temperature applications.

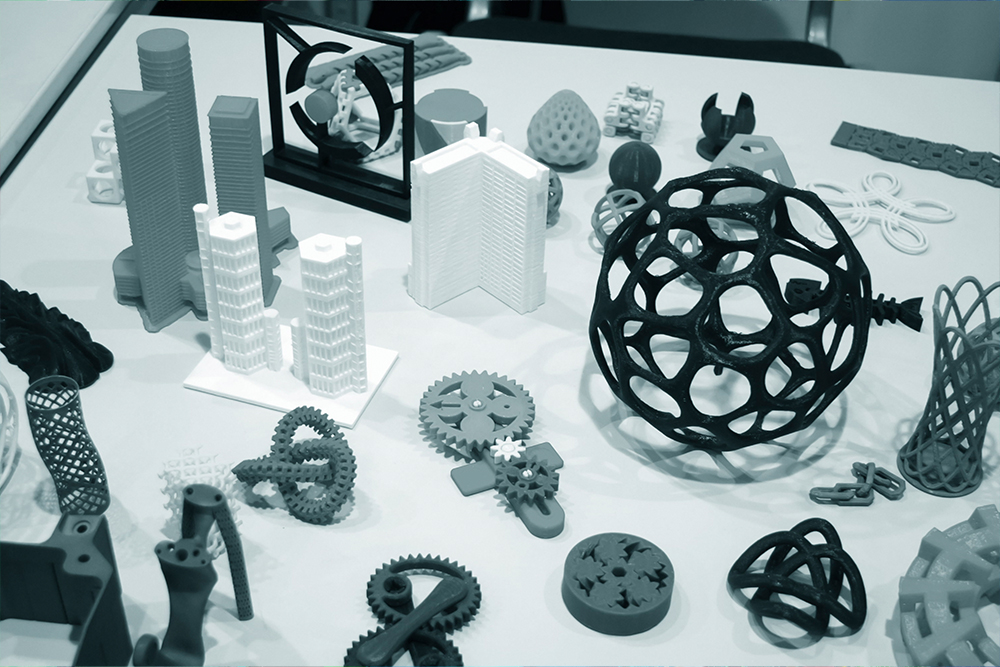

Machinability : Engineering plastics are generally easy to process and can be shaped into different shapes, enabling a variety of product designs to be realized.

Applications of Engineering Plastics

Automotive Industry: Engineering plastics are used in the automotive industry for engine parts, interior trim parts, body components, and many other applications.

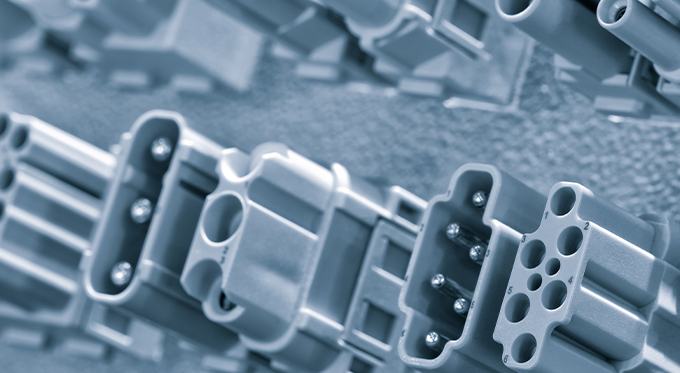

Electronics Industry: Many parts of electronic devices are manufactured from engineering plastics. These plastics are used in insulation, housing and components.

Medical Industry: Medical devices and equipment are often manufactured from engineering plastics. These materials are used in many parts of hospital equipment , surgical instruments and medical devices.

Machinery Industry: Machinery parts and equipment are produced from engineering plastics. These materials are used in applications requiring high strength and durability.

Packaging Industry: Food, beverage and industrial packaging is produced from engineering plastics. These materials are used in packaging applications that require durability, chemical resistance and sealing.

Advantages and Result

Engineering plastics have many advantages, making them a popular choice in industrial applications. Properties such as high durability, strength, chemical resistance and processability enable engineering plastics to have a wide range of uses. As a result, engineering plastics are considered reliable, durable and diverse material options in industrial engineering projects.