Human Spare Parts In Markets

It’s like science fiction, right? Many writers told the human race with fantastic stories in their books, for example Frankenstein. The directors made many films about this subject and told about the self-destruction of human beings, for example Elysium. The painters, like Salvador Dali, wanted to stop time in their paintings so that humanity could be imprisoned over the years. Healthy eating, stress management and detox are not enough for eternal life. Human life is biologically limited to certain life years. Taking good care of our body can only make our lives 10 years or 20 years longer. Technology has effects on our lives as in all areas. Scientists have realized a new revolution with 3D printers while they were working on sheep cloning and DNA studies. But how?

3D printers work with a manufacturing method called Additive Manufacturing. Although many raw materials are used for printing, mostly thermo-plastic materials, often referred to as filaments, are used.

3D printers need a 3D model and design to work. Drawings designed with a CAD (Computer Aided Design) program such as AutoCAD, Solidworks, 3DsMax, or objects scanned with a 3D scanner are exported in the stl extension. The 3D printer detects the file in the .stl extension and performs printing.

I want to go into a little more detail of the working principle. Before starting the printing process, the head area called the nozzle which is at the end of the printer must reach a certain temperature. This is because 3D printing is done by laying the melted filament over and over. In order to spread the filament evenly, it must melt at high temperature as it exits the head. As soon as the filament which melts out of the head is spread on the surface, it freezes and becomes solid. Once all the layers have been completed, the model is ready in solid form.

There is no limit to what you can do with the 3D Printer. Product prototyping, home decoration, souvenirs are already common. For example, you can print a vase that you have designed for your flowers or you find a ready-made design. You can place 3D prints on the body of a robot you intend to make, and you can even make the whole body with 3D printing.

As I mentioned before, the use of the 3D printer is not limited to these. With 3D printers that print chocolate, you can get your own chocolate. Apart from chocolate, 3D printer technology is developing rapidly in the food industry.

NASA (National Aerospace Agency) astronauts get the materials they need by printing them with a special 3D printer that they sent to space. 3D printer technology has also found its place in wearable technology and textiles. 3D printing technology is used in orthopedic solutions, garments, accessories such as watches and wristbands. Famous sports brands have recently started mass production with 3D printing on the soles and various parts of their sneakers. When we look at this process, it is seen that they have overcome the problems of high cost and mass production.

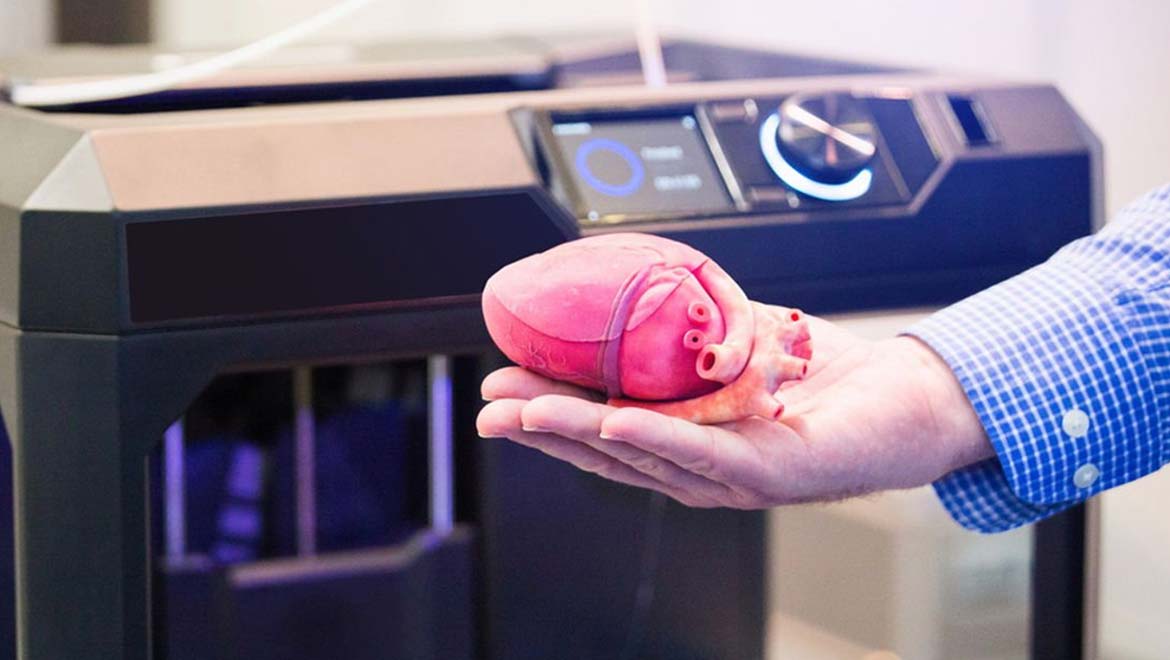

The developments in the medical field are highly positive. Prostheses and anatomy models for patients are obtained with 3D printer. There is even 3D print organs. In the Netherlands, the skull of a 23-year-old patient and a skull produced with a 3D printer are replaced and the patient’s positive response to the operation is obtained.

As a positive response, he has returned to work only 3 months after the skull was replaced.

University of Health Sciences in Turkey Gulhane Medical Design and Manufacturing Center (METU I), is ready to produce body parts with 3D printer.

It is not known how much impact it will have on the cycle of nature and how depletion of living spaces and resources will be affected, but human spare parts appear to be on the shelves of medical markets very soon