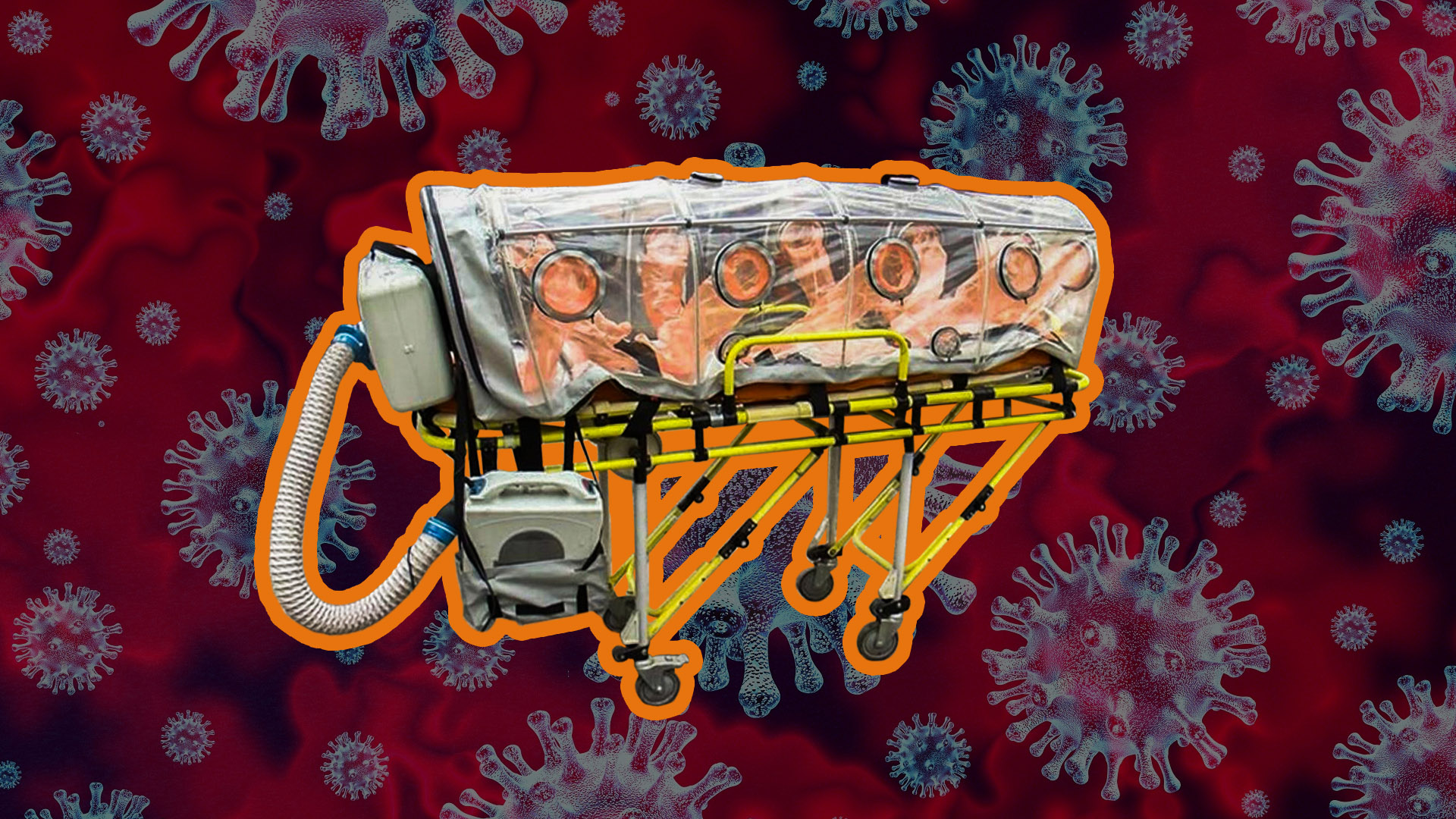

Quarantine Stretcher

There is a panic seeing the quarantine stretcher .... it's normal for us to panic. The coronavirus, declared as a pandemic in the world, is not a virus to be joked. However, quarantine stretchers used in coronavirus are not new in our lives. Ebola-like virus in negative pressure and stretchers carrying the virus used in patients since 2010 in Turkey. The fact that we see stretchers used for preventive and protective purposes in airborne diseases is only related to our awareness.

.jpg)

Stretchers, which are completely isolated from the external environment, bring fresh air to the patient, while removing the infected air from the patient by removing it from the filter. Fresh air is taken in through the holes on the back of the stretcher, and after the patient breathes, air circulation is provided by removing the filter to prevent contamination. The integrated bed can be adjusted for both knee angle and backrest, providing greater comfort for the patient and better conditions for clinical procedures. Visibility through transparent hardtop enables better communication between the patient and the environment. Adjusting the position improves breathing and communication, thereby contributing to reducing anxiety. There are arms around the stretcher. If any intervention is needed during the transfer of the patient, all the necessary interventions are made during the transfer with the help of these arms between the front and between. Unlike other stretchers, quarantine stretchers provide a risk-free patient transfer by completely eliminating the risk of transmission to healthcare professionals or someone else, as the patient is fully isolated during patient transfer.

.jpg)

Quarantine stretchers; patient comfort features can be described as intervention stations, ventilation system, operator connection points, waste bag, medical connections and ventilator port.

The chamber liner is made of TPU film and reinforced by placing ABS support posts along both sides of the structure. It can be shaped easily due to its TPU properties, it is preferred in quarantine stretchers due to its wide application range, wear resistance, flexibility and harmless to human health. Thermoplastic Polyurethane or TPU is called the bridge between rubbers and plastics. The material looks rubber-like, which means it can be extremely flexible, durable and smooth to the touch. All these features and composite versatility make TPU widely available for coatings, components and customer products in many industries.

There are no people who do not expect industrial quarantine stretchers from the manufacturers and produce their own solutions. 7 friends from the Erzurum Regional Training and Research Hospital (BEAH) technical unit produced a quarantine stretcher consisting entirely of waste materials. In the workshop of the hospital, 7 friends using old incubators, veterinary gloves, transparent tarp, iron profiles, metal, seat belts, pvc pipes made a closed insulation stretcher on four sides in about 16 hours. Serial production will not be possible, but it will seem that the coronavirus will regain the fact that it produces cumbersome ideas and efforts with human technology. Who knows…