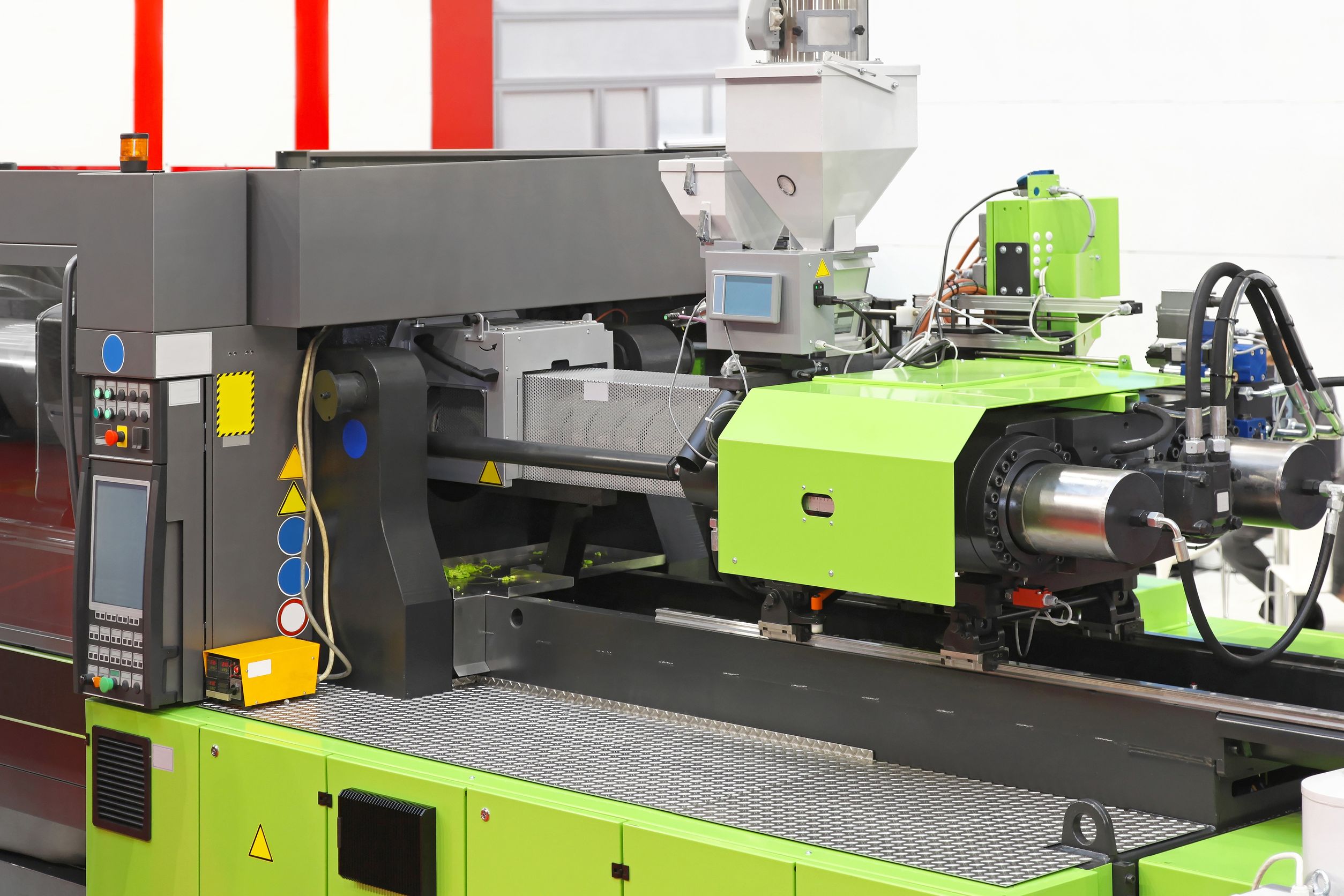

Advantages Of Plastıc Injectıon Moldıng

If you follow our magazine, you are familiar with plastic injection molding, one of the most popular methods for manufacturing plastic parts. This technology consists of filling the plastic material into a heated drum. The material is mixed, then guided to a mold cavity in which it is shaped and cured in the final product. The information you’ve probably missed is that plastic injection molding has many advantages and benefits compared to comparative plastic processing and manufacturing methods.

Here are some reasons why plastic injection molding is preferred:

1) Accurate

Plastic injection molding is a method that is sensitive enough to produce almost any type of plastic part. There are some design limitations, but the molds make the finished product very precise. In fact, accuracy is typically within 0.005 inches.

2) Quick

There is a reason why plastic injection molding is one of the preferred technologies, even if it is not the most common for long production processes. He also be fast. How fast? Although the speed depends on the complexity of the mold, the process is usually completed only in periods of about 15 to 30 seconds.

3) Low labor costs

Injection molding equipment typically operates automatically, requiring minimal supervision to streamline operations and ensure production continuity.

4) Talented

Nowadays, long-lasting products are paid great attention to, so it is common for product developers to select processes that will benefit the environment and minimize waste. Plastic injection molding is not only an efficient, effective process, but also successful. This is because; the use of only the required amount of plastic to form the part and the excess plastic can be collected and recycled after use.

5) Flexibility

In addition to being an accurate production process, plastic injection molding is also a flexible method. However, we mean that it is simple to change the type of material being produced and the color from which the product is produced.

6) Ideal for Building High Strength Components

Another advantage of the plastic injection molding process is the ability to add fillers to the components during processing. It is to reduce the density of liquid plastic and to give more strength to the finished part. Plastic injection molding is an ideal process for sectors or products where parts need to be strong.

7) Smooth Final View

Plastic injection molding is often a process in which the manufactured parts require very little or too much processing for the final treatment. Because all the pieces coming out of the mold are closest to a finished appearance. Turning back to benefiting from item 3 in this list, another example would be an example of the low labor costs of injection molding.

8) Injection Molding

Injection molding machines can process two or more different plastics at the same time.

9) Long-Term Cost-Effective Plastic Processing

Making the first mold can be expensive and cost several thousand pounds. However, once the mold is formed, you can create a huge amount of plastic components at a minimum cost. Therefore, the molds to be mass-produced will compensate the cost.

10) Widely Used

Plastic injection molding is one of the most popular plastic manufacturing processes. Just look around, you’ll be sure to see many products produced during this process.