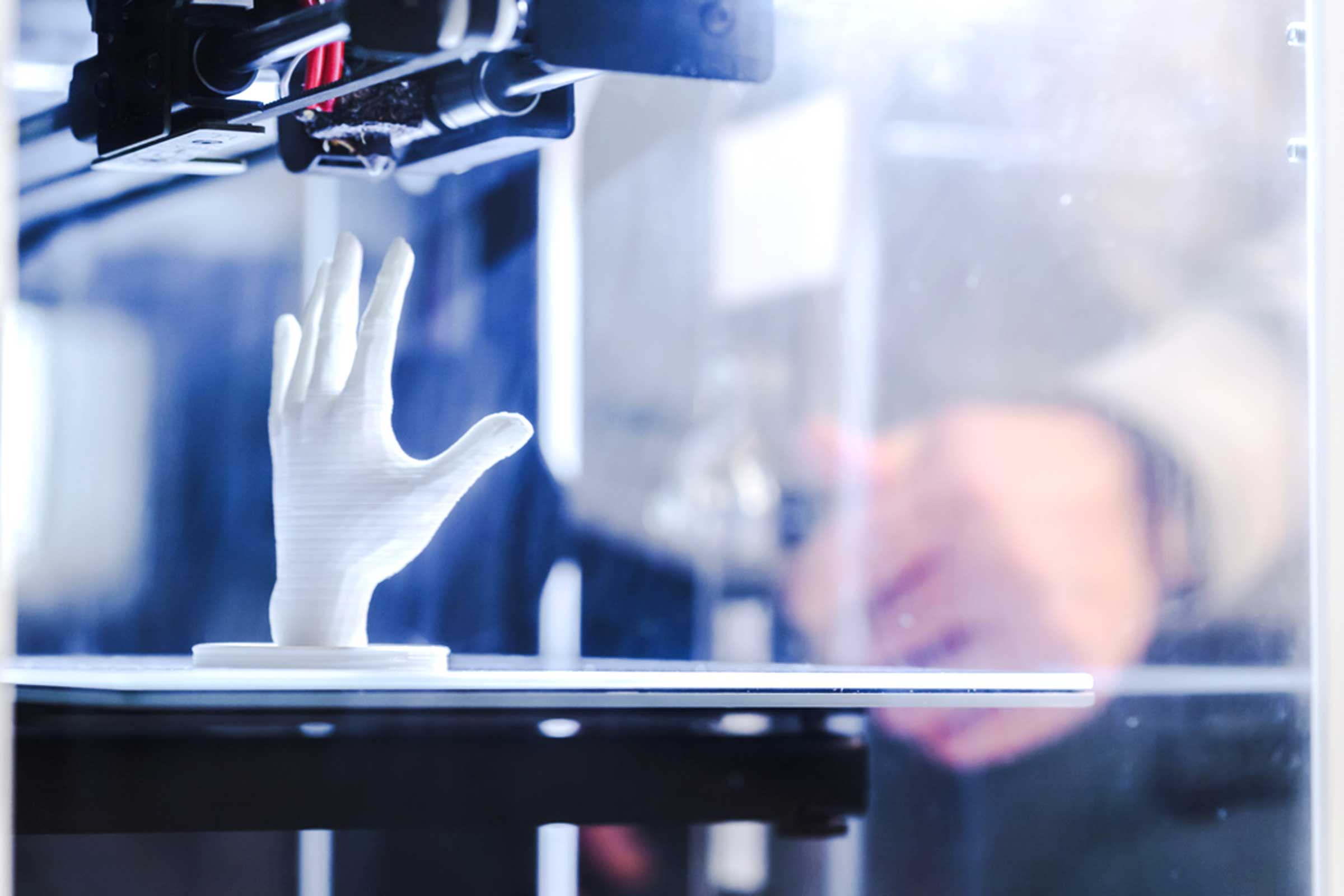

Materıals Used In 3d Prıntıng

From an artificial skull made of acrylic to special candies created from chocolate, the world of 3D printing continues to be even more amazing. In this article, we will talk about 3D printers, using various materials such as metal, ceramics, sugar and styrofoam, enabling people to produce almost anything. Of course, plastic is the first to make 3D printing possible, and plastic remains one of the most common and versatile materials used in 3D printing.

Polylactic Acid (PLA)

It is probably not surprising that one of the most widely used bioplastics in the world is dominant in 3D printing. PLA, a biodegradable thermoplastic aliphatic polyester, is produced from renewable, organic sources such as corn starch or sugar cane. It is widely used for food packaging, biodegradable medical devices and implant manufacturing. PLA is perfect for 3D printing because it is easy to use, eco-friendly, available in various colors. Can be used as resin or filament.

Polietilen Tereftalat (PETG)

PETG (Polyethylene Terephthalate Glycol-modified) is a thermoplastic material. Soft drinks, food and beverage containers, kitchen utensils, cookie molds and synthetic fiber. PETG, which is an alternative to ABS and PLA, has a stronger and more flexible structure than ABS. It is as easy to print as PLA and is fully recyclable.

Akrilonitril Bütadien Stiren (ABS)

ABS, a terpolymer produced by polymerizing styrene and acrylonitrile with polybutadiene, is another plastic commonly used in 3D printing. Beginners prefer it especially because of its ease of use in the form of filaments and because it is strong, heat resistant, cost effective and flexible. However, because it is petroleum-based and biodegradable, ABS loses its popularity among people with 3D hobbies who prefer PLA’s more environmentally friendly nature.

Polivinil Alkol (PVA)

PVA, a water-soluble plastic, is most commonly used as an adhesive, thickener or packaging film and is used to improve print quality. In the world of 3D printing, PVA is not necessarily used to make the finished product. Instead, it is used to create a support structure for parts of a product that may become skewed or collapsed during printing. In printers with two or more extrusion presses, the user may use one or more extruders to form the support structure of the PVA, while others attempt to create the actual product from the materials. When printed, the finished and hardened product can be immersed in water until the PVA support structure is dissolved.

Of course, the range of materials, processes and applications that can be used in 3D printing continues to expand and develop. Nevertheless, one of the most surprising developments in production begins with the initial space-age material, plastic.