Plastıc Dıssolve Bacterıa Found

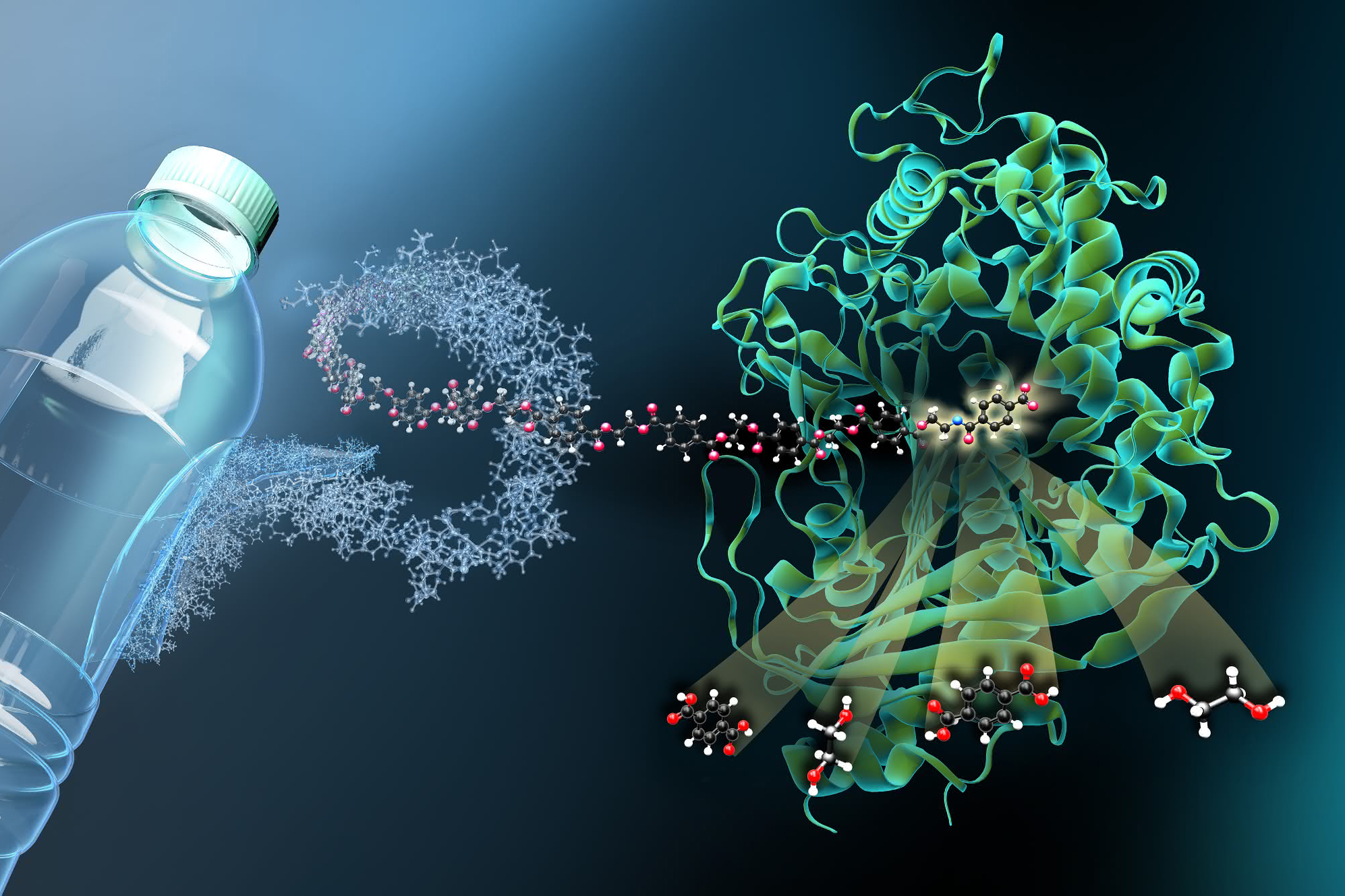

Scientists have developed an enzyme that can dissolve plastics that are thrown into the nature by us and cause environmental pollution. PETs used in plastic bottles may take a long time to dissolve in nature. But thanks to the enzyme PETase, it will be possible to dissolve plastics within a few days. In our article named “Is the solution to the plastic waste of the world a mushroom?” we mentioned a similar discovery.

With such efforts and nature solutions, recycling incentives and investments should be made instead of prohibitions. This can revolutionize plastic recycling, allowing plastics to be reused more efficiently. The enzyme discovered in a landfill in Japan is secreted by a bacteria that eats PET in nature.

The bacteria Ideonella Sakaiensis survives with the energy it produces by eating plastic. Researchers found this type in 2016 at a plastic recycling facility in the port city of Sakai. Professor John McGeehan, who was involved in the research, pointed out that plastic has existed in large quantities in nature for only 50 years, while this is a short period of time for a bacterium to evolve.

Polyesters, a group of plastics including PETs, are also formed in nature. Prof McGeehan of Portsmouth University said that these polyesters protect plant leaves, bacteria have evolved to eat them for millions of years, but the transition to eating PET from these polyesters is at unexpected rapidity. After figuring out how PETase works, scientists have made this enzyme more efficient with small additions.

This shows that PETase’s evolution has not been completed, and that it has evolved so much in a short period of 50 years. Researchers encountered another surprise when experimenting with the enzyme in plant-based PEF plastic, an alternative to PET: PETase was able to dissolve PEFs more successfully.

Speaking to BBC News, Prof McGeehan said that the quality of polyesters in existing recycling facilities decreases with each recycling, after a while it becomes unusable, but PETase will separate the plastic into the basic building blocks and provide better recycling.

The production of the enzyme at an industrial level requires at least several years. For this, PET must be made to dissolve faster. Who knows, maybe they want to cooperate with the newly found fungus.

The research carried out at the University of Portsmoth includes doctoral students and even undergraduate students. When I visited their labs, I noticed their excitement was contagious. Developing PET was an intelligent engineering and they are now very happy to have found a way to solve it again. Growing with the threat of plastic pollution, these people have great motivation to solve this problem.

But it will also take a great deal of effort to make this enzyme available in real life. Being able to produce this enzyme inexpensively is one of the obstacles that must be overcome, and the other is to use it at an industrial level. This is an example of accelerated science. A species of bacteria evolved to survive by eating plastic in just a few years. The enzyme that dissolves PETs has just been discovered. We now have this enzyme further developed by scientists. Such a development is vital in the fight against the plastic pollution crisis.