The Brand Of The Mold

It was a hard headpiece, but not a lie, injection molding and mold making is something that should not be taken lightly. Otherwise, you really speak as much as your mold ...

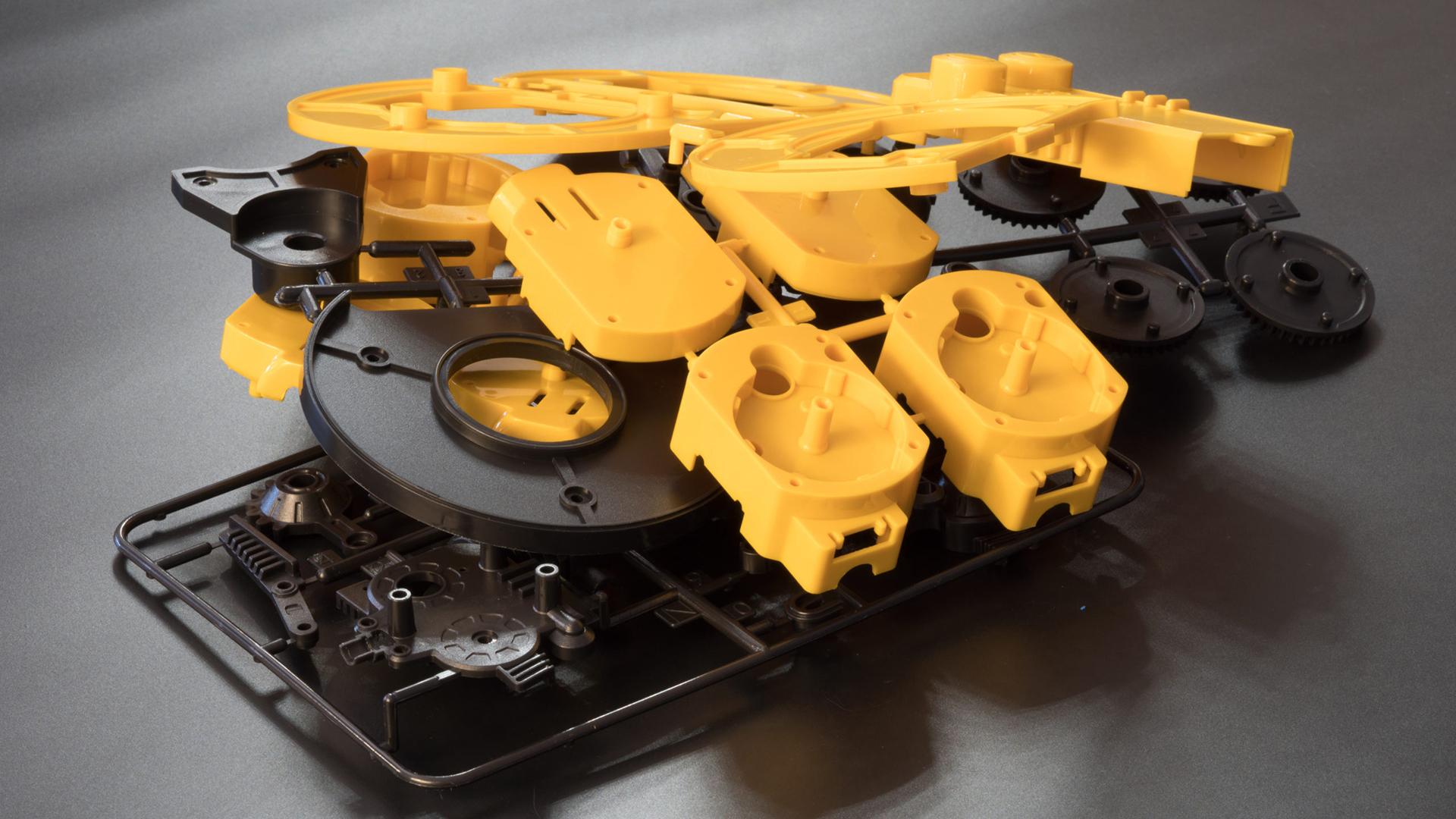

You produce plastic lids or plastic drums, no plastic chairs or plastic buckets… no end, examples, how many things we produced by injection molding !!! Many products that make our lives easier and are in the center of our lives are produced by plastic injection. Injection molding and mold production are at the very center of plastic injection production. If we were to talk about five common misconceptions about injection molding and mold making, would we start a new discussion?

.jpg)

Keeping up with the latest manufacturing best practices is a wise and crucial decision regardless of whether it is related to CNC machining, 3D printing or injection molding as in this case. Injection molding is the most efficient and cost effective process for mass production of plastic parts. Millions of parts can be produced to exacting tolerances in a very short time. But first you have to create a mold, and this part of the process, like the injection molding process itself, grapples with a series of myths and misunderstandings. Here are five of the most common legends.

Any shape can be molded As in mechanical engineering, a part design must be manufacturable. It is not possible to mold every shape. The plastic part must be highly moldable. If there is an error or the moldability is poor, you will find yourself facing all kinds of production problems and quality issues during the mold making process. The misconception that plastic of any geometry can be molded perfectly is false and misleading. Most designs need to be changed if they cannot be shaped to at least 90% of the original idea. Perfection depends on the balance of melt flow and the channels through which heat is exchanged. It will be seen that if the plastic does not freeze uniformly, the mold will not work for all purposes and purposes.

.jpg)

Plastic injection molding is not ideal for prototyping. Often it is assumed to be a difficult technique in the sense that it is not cost-effective and takes a lot of time. Generally, other techniques are used for prototyping, but the biggest problem with this is the lack of similarity with the final product. In fact, injection molding methods provide the most cost effective solution for creating samples that look like the finished product. It can create high-quality prototypes and represent the final product more accurately than any other option at your disposal. This allows you to get an idea of the finished product so you can make the necessary changes without affecting the cost.

The production cycle of the molds is short The durability and production cycles of your molds are highly dependent on your requirements. For example, steel molds are made and developed for long-run production. Molds developed using other materials make prototyping and other short-term productions. Regardless of the material used, the molds are said to be highly durable and able to run continuously without errors over hundreds of thousands of cycles. This means it will produce thousands of parts for you.

Mold making produces a lot of scrap We all know that using a CNC machine requires trained professionals, but this job is sometimes handed over to engineers with minimal training. An experienced CNC operator is often involved in loading, unloading, cycle activation and monitoring, workpiece measurement, evaluation, adjustments, etc. in the workplace. It deals with many tasks, including. Therefore, it makes sense to only employ highly experienced CNC operators who can minimize scrap and equip them with the best machines in the industry. What's more, injection molding and mold making produce the least amount of scrap compared to other traditional manufacturing processes. Older, less advanced processes can often consume a significant portion of the original plastic sheet or block. The four main areas of the machine are responsible for the low amount of waste plastic.

The last example of the misconception that only injection molding parameters can solve quality problems. Injection molding parameters are not the only way to fix the molding process. Restrictions such as dimensional inaccuracies, skew, sag marks and shrinkage can be partially removed with the help of mold design. A job that has worked perfectly before may not necessarily work perfectly forever. It is equally important that you use the most effective mold and part designs when setting injection molding parameters. Therefore, it is possible to say that the quality of your end product can be determined to a large extent before production begins.

As a result, whether you are a good engineer or a good CNC operator or a good manufacturer starts with injection molding and mold making, maintaining stability by programming the entire production.